By David J. Lingrey, Environmental Technologies, Inc.

Introduction

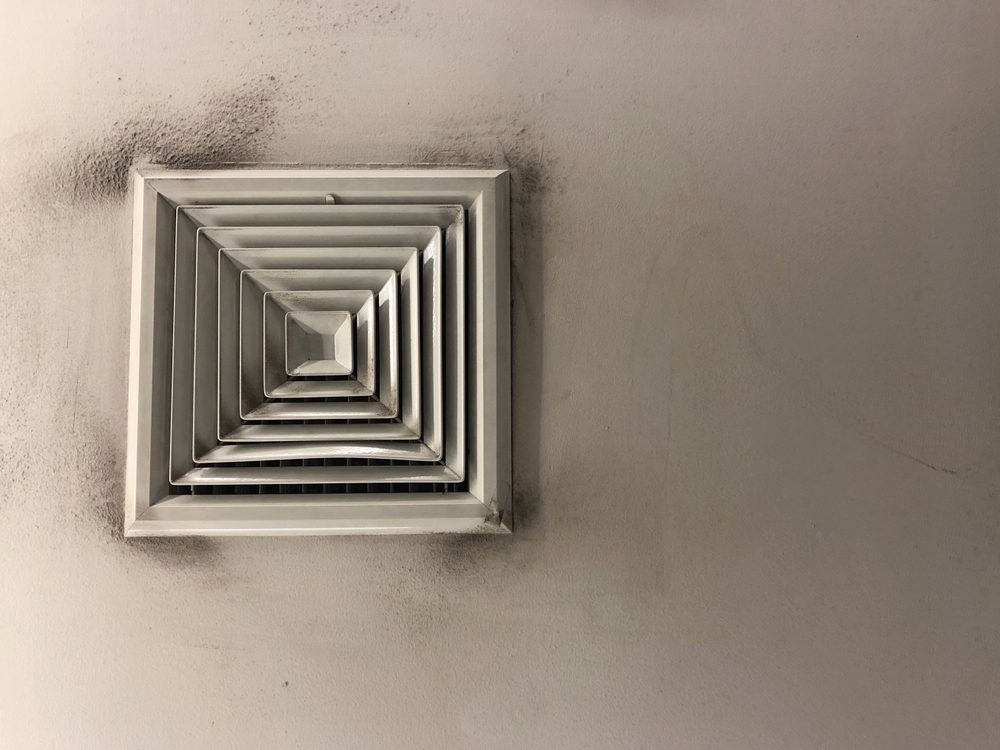

Mold growth in buildings and HVAC systems has been implicated as a contributor to poor Indoor Air Quality (IAQ) and the so-called Sick Building Syndrome. While HVAC, themselves are not the cause of mold proliferation in buildings, the very nature of HVAC system design and their typical operating limits may provide an acceptable niche where mold growth can occur. Once unchecked mold growth occurs, the HVAC system acts as a perfect vehicle to spread mold spores in the building through the air distribution system. Once this occurs, costs associated with mold remediation have been known to be quite exorbitant. To control mold growth and keep it from becoming problematic, one must understand the basic premise behind its growth and control.

Mold

Mold and mildew are a type of fungi. Fungi are normally harmless to humans, however many fungi can cause respiratory irritation and allergic reactions in those susceptible. Fungal infections may occur in those with immune suppressed systems but rarely are a threat in the healthy population.

Mold proliferates through the production of spores. Spores are capable of surviving very harsh environments and may lie dormant for many years until the right conditions exist for mold growth.

Fungal spores range in size from 1 micron to slightly less than 100 microns. Studies have shown that with adequate filtration a majority of particles in this size range can be captured.

Fungi are present in all climates and environments on Earth. Many thousands of species of fungi exist, but only a small number of fungal species are generally implicated in IAQ problems. Some of those of concern are Aspergillus spp., Penicillium spp., and Stachybotrys spp. Other fungal species known to grow in indoor environments are identified in references associated with Mycology and IAQ.

Fungi normally exist in the outdoor environment where they go about their work breaking down all forms of organic debris into smaller molecules where other life forms can consume them. Fungal spores find there way into buildings in various ways, primarily during the construction process, through infiltration, outside air ventilation, and on our clothing and personnel belongings. Typically, indoor spore level counts are much less than outdoor concentrations. However, because spores do exist indoors, it only takes the right combination of factors for mold growth to occur within the walls of a building, in or on its furnishings, and within HVAC systems and ductwork. Various studies have shown that when an indoor fungal bloom exists, the indoor spore concentrations can easily exceed those found in outdoor environments. When mold problems become prevalent, certain chemical compounds can be produced by the mold, resulting in the musty odors and poor air quality commonly associated with mold growth. It is at this point, that concerns for the health of a buildingís inhabitants are generally voiced.

Fungi require four essential elements for growth:

1. Acceptable temperature range ñ Each fungus has an optimal temperature range that allows for its growth.

2. A nutrient source ñ As stated previously, fungi consume organic (carbon-based) matter. This includes, paper and wood products, carpet, wall coverings, organic dust particles, paint, adhesives, plastics, fabrics and many other building products.

3. Presence of a consistent moisture source ñ Excessive humidity ratios within the walls of the building, furnishings, and the moisture produced during the cooling / dehumidification process in the form of condensation in HVAC systems can be capable of supporting mold growth.

4. Viable spores ñ Spores are present in all buildings and systems.

When these conditions are present, spores will germinate and grow. Remove one of the four elements and the growth process will be inhibited or nonexistent. This is the basic premise for control of mold in HVAC equipment.

Design for Mold

Control Temperature Range

Temperature ranges where HVAC systems operate are typically well within the acceptable tolerances for the molds stated. Because the temperature must remain in the range acceptable for human comfort, fungi control through this method is not practical.

Nutrient Control

Control of the nutrient source is obtained by selecting materials that inhibit the availability of nutrients on or in their surfaces. To reduce the nutrient levels within the unit, fibrous glass insulation should be eliminated and filters carefully selected. Interior surfaces of the unit should be smooth, durable, and washable. Double wall construction is particularly effective because the internal galvanized steel liner does not readily support nutrient adhesion and mold growth.

Insulation

Closed Cell Foam insulation should be used exclusively in the HVAC equipment. The surface of which is smooth, durable to impact, and resistant against damage thus inhibiting the potential for nutrient adhesion onto or within its surfaces.

Filtration

The use of MERV 6 or higher efficiency filters will inhibit the passage of a large portion of the mold spores into the HVAC unit. HEPA filters have been shown particularly effective at reducing mold spore concentrations. Filters should be selected with construction consisting of synthetic materials to eliminate cardboard, cotton, or other organic elements thereby eliminating another potential food source for the fungi. Additionally, by using filters that are comprised entirely of synthetic media and frames, there are no moisture absorbing materials that can support mold growth. Proper maintenance of the filter media is essential for continued filtration effectiveness and nutrient control.

Moisture Control

Moisture control is the important element associated with the effectiveness for mold control. To achieve a high quality indoor environment, exterior moisture must be prevented from entering the building by using properly located vapor barriers, treating makeup air through dehumidification devices and providing positive air pressure to prevent infiltration of humid exterior air. Additionally, water vapor present in the interior air must not be allowed to condense on cold interior surfaces, and plumbing systems must be designed, installed and maintained to prevent liquid water from wetting building materials and furnishings.

Within HVAC systems, it is essential that all condensation be controlled so it freely drains from the unit. Standing water in condensate pans is one of the largest contributors to mold proliferation within HVAC systems. The unit must be properly insulated, sealed and caulked where necessary to prevent condensation on metal surfaces and within the insulation in order to keep mold spores from germinating. The HVAC unit should be equipped with the following features specifically designed and selected to meet these requirements.

Closed Cell Foam Insulation

The elastomeric material provides for low water vapor permeability and will not support moisture absorption. By design, the closed cell structure of the insulation acts as its own vapor barrier. The smooth integral skin is a tough impermeable surface that is tear and puncture resistant and can be cleaned. The lining meets the requirements for ASTM G-21 for mold growth resistance. Studies have shown that fungal levels on the exterior surfaces of closed cell foam insulation are many thousands of times less than those found on fibrous glass insulation.

IAQ Drain Pan

The condensate drain pan must be designed with features that eliminate the potential for standing water. The drain pan should be sloped toward the drain connection to allow for positive drainage and fabricated from stainless steel for corrosion protection and cleanliness. The pan must be externally lined with closed cell insulation to prevent surface condensation. The drain connection is best located on the bottom of the pan to facilitate drainage of condensation. To prevent drain line blockage and condensate standing water or overflow, a drain connection comprised of an easily removable, large diameter P-trap for cleaning and service should be used.

Coil Design

Large coil face areas result in low coil face velocities thereby eliminating the potential for condensation blow-off further increasing the effectiveness of moisture control. Coils designed with adequate dehumidification capacity to remove water vapor from the conditioned space are also recommended.

Dehumidification Control

Both the United States Environmental Protection Agency (EPA) and ANSI/ASHRAE Standard 62-2001- Ventilation for Acceptable Indoor Air Quality recommend that indoor relative humidity be maintained below 60% to minimize the potential for fungal growth. While high relative humidity can contribute to mold growth, it is also important to control the moisture content within hygroscopic materials. Eliminating and controlling sources of condensation, water leaks, flooding, and vapor infiltration will have a significant impact on the control of fungal growth within buildings. The HVAC system and the building design must work in concert toward minimizing mold growth through the control of moisture.

To help maintain proper humidity levels within the conditioned space, buildings must be designed and built to resist moisture migration into the building envelope. Effective use of vapor barriers, positive air pressure control, pretreatment of outside air and proper design of water conveyance systems have been shown to be effective in reducing indoor humidity ratios. Further discussion on the methods used to prevent moisture migration in construction is beyond the scope of this document. Consultation of references that specifically define these processes and practices is recommended.

The unit design must allow for dehumidification during part load conditions. Typical features used to accomplish this are as follows:

1. Variable Speed Fan Control: Variable speed fan control based on sensible heat temperature control with dehumidification override. The controller (thermostat / dehumidification) automatically adjusts fan speed based on cooling capacity and or humidity setpoint. The fan speed adjustment reduces airflow through the cooling coil lowering the supply air temperature at a given load thus removing more moisture from the return air. Fan speed control based on dehumidification setpoint, allows the unit to operate longer thus reducing the humidity swings normally encountered when strictly using sensible temperature control schemes. In some instances, a reheat system must be used to raise the leaving air temperature within acceptable range of the temperature setpoint.

2. Bypass Damper Control: Bypass Damper control reduces the airflow through the cooling coil by modulating a by-pass damper open as space humidity rises. The by-pass method mixes cool dry air leaving the cooling coil with return air. While in this mode, the chilled water temperature and flow rates remain constant optimizing the dehumidification effect through the cooling coil as the airflow rate is reduced through the coil.

Other methods of dehumidification control exist that are not mentioned in this paper. Some of those methods are the use of desiccant wheels; heat pipes; run around loops and direct expansion mechanical dehumidifiers. References associated with dehumidification should be consulted for descriptions of these processes.

Cleaning and Maintenance

Proper maintenance is essential to maintain the effectiveness of mold control features designed into HVAC equipment. Without periodic inspections, preventative maintenance, and corrective repairs, HVAC systems are prone to specific failure modes that will contribute to an increased potential for mold proliferation. The expenses associated with proper maintenance will easily offset typical costs associated with mold remediation.

Filters must be replaced on a monthly or by-monthly schedule to prevent accumulation of organic debris that acts as a nutrient source for mold to feed on.

Cooling coils should be inspected quarterly and if necessary cleaned with appropriate cleaning solutions, taking care not to spill the solution into the HVAC unit cavity.

The Condensate Drain Pan and P-trap must be inspected quarterly for signs of debris and drain line blockage. Standing water is indicative of this problem. Cleaning of the pan and flushing the drain line must be performed if necessary. The use of biocide tablets has been shown effective against mold growth within condensate pans.

Cabinets should be inspected annually for signs of water and air leaks, insulation degradation, and gasket damage. Repairs must be implemented as necessary.

Summary

While specific design features in HVAC equipment can help quell the problems associated with fungal growth inside the HVAC unit, it will not reduce problems that may occur within the building. Sound design practices based on specific principles to eliminate moisture within the building envelope are necessary. The use of vapor barriers, reduction of infiltration of humid outdoor air through building pressurization control schemes, pre-treatment of makeup air, and other moisture control methodology is beyond the scope of this document. Consult building design references specifically written on this subject.

It has been shown through various scientific studies that mold can be controlled by the careful selection of components for use within the HVAC system and through moisture control strategies on an unitary level and on a building basis. It is therefore recommended that the HVAC system and building design work together toward mold reduction.

For the mold reduction strategy to remain effective within the HVAC unit, proper maintenance, and service is necessary. Negligence in routine service will only lead toward ineffectiveness of the mold reduction design features and concepts and hence may allow for unchecked mold growth.

Bibliography

1. ANSI/ASHRAE Standard 62.1-2001 ñ Ventilation for Acceptable Indoor Air Quality

2. Harriman, Lew, Brundrett, Geoff, Kittler, Reinhold. – Humidity Control Design Guide for Commercial and Institutional Buildings. ASHRAE 2001

3. Department of Architectural Engineering. Pennsylvania State University. Aerobiological Engineering, Fungi and Bacteria in Ventilation Systems. State College, PA.

4. Department of Biology. Pennsylvania State University. Aerobiological Engineering, Airborne Pathogen Database, Fungi. State College, PA.

5. Bahnfleth, William, Kowalski, W. ìAirborne Respiratory Diseases and Mechanical Systems for Control of Microbes.î HPAC Engineering. July 1998: 34 – 48

6. Lstiburek, Joseph. ìMoisture Control for Buildings.î ASHRAE Journal, February 2002: 36 ñ41

7. Schoen, Lawrence J. Controlling Moisture in Building Mechanical Systems. ASHRAE IAQ 2001

8. Thomann, W., Tulis, J. Fungal Contamination of HVAC Surfaces: The Role of the Dew Point in Microbial Amplification. Proceedings of the 1996 ASHRAE IAQ Conference, Baltimore, MD October 6-8 1996. ASHRAE Atlanta, GA ISBN 1-883413-41-9..

9. Burge, H. “Fungi: How they grow and their effects on human health.” HPAC 69(6), June 1997

10. Ellringer, Paul, J., S.C. Hendrickson, Chin S. Yang, and Katy Boone. Fungal Levels on Interior Surfaces of Ventilation Ductwork: Closed Cell Foam Insulation Versus Fibrous Glass Insulation and Galvanized Metal. ASHRAE IAQ 2001

11. Buttner, Mark, P., and Linda D. Stetzenbach. Fungal Spores Dispersed from Fiberglass Ductboard, Fiberglass Liner, and Galvanized Metal Air Handling System Duct Material. ASHRAE IAQ 2001

12. Cheong, C. D., H. G. Neumeister-Kemp, Peter W. Dingle, G.E. St. J. Hardy. The Use of HEPA Air Filters to Control Airborne Indoor Fungi. ASHRAE IAQ 2001