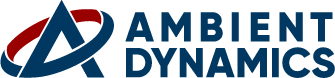

Microchannel Coils

Microchannel Coils Overview

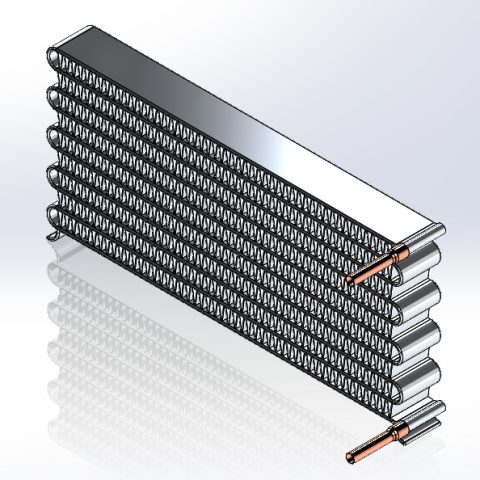

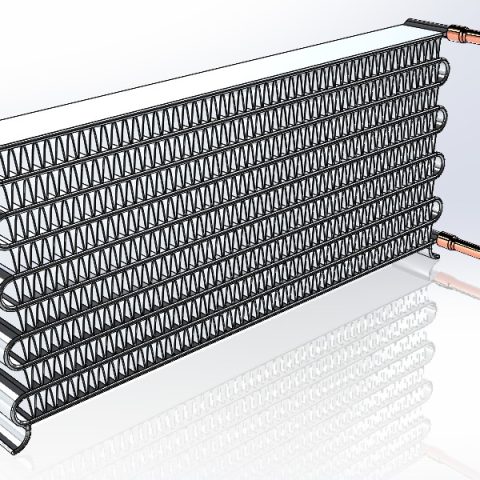

Microchannel coils are state-of-the-art heat exchanger systems featuring small, flat channels designed to optimize the transfer of heat. These channels are much smaller than traditional tube-and-fin coils, which allows them to deliver superior heat exchange in a more compact and lightweight package.

Why Choose Microchannel Coils?

- Enhanced Efficiency: Microchannel coils offer higher heat transfer efficiency than traditional coils due to their compact design and increased surface area for heat exchange. This leads to better performance and lower energy consumption.

- Compact & Lightweight: The slim, lightweight design of microchannel coils allows for smaller system footprints, making them ideal for applications where space is limited, such as in automotive air conditioning, refrigeration, and compact HVAC systems.

- Corrosion Resistance: The construction materials for microchannel coils are often more resistant to corrosion compared to traditional coils, ensuring longer-lasting durability in various environments.

- Lower Environmental Impact: Microchannel coils help systems run more efficiently, reducing the energy needed for operation and ultimately contributing to a reduction in environmental impact.

- Cost-Effective: Because of their superior heat transfer, microchannel coils can help reduce operational costs over time, making them a smart investment for energy-conscious businesses.

- Available configurations: Evaporator, Condenser, Liquid Coils, and Serpentin coils. OEM replacements available.

In summary, microchannel coils represent the next level of heat exchanger technology, offering impressive efficiency, durability, and compactness for a range of industries. For businesses looking to reduce operational costs, improve system performance, and adopt more sustainable practices, microchannel coils are an investment that pays off in the long run.

GALLERY

CONSTRUCTION OPTIONS

|

Component |

Material |

Design Pressure (BAR) |

|

Condenser |

Aluminum Alloy |

32, 45 (HFC, HFO, Natural) |

|

Evaporator |

Aluminum Alloy |

32, 45 (HFC, HFO, Natural) |

|

Serpentine |

Aluminum Alloy |

32, 45 (HFC, HFO, Natural) |

|

Liquid |

Aluminum Alloy |

10, 20 (Water, Glycol, Oils, Special) |

|

Protective Coating: |

E-Coating, TCP Coating, Nano Coating, UV Protection |

|

|

Special Coating: |

Hydrophilic, Hydrophobic, Paint |

|

Certification stamps